Why Choose Stainless Steel for Material Handling Equipment?

Stainless steel is a preferred material in the manufacturing of material handling equipment due to its numerous advantages. Its unique properties make it suitable for various industrial applications, ensuring durability, safety, and efficiency.

Key Benefits of Stainless Steel

- Corrosion Resistance: Stainless steel's ability to resist corrosion ensures longevity and reliability, even in harsh environments.

- Durability: With high tensile strength, stainless steel can withstand heavy loads and impacts, making it ideal for industrial use.

- Hygienic Properties: The non-porous surface of stainless steel prevents bacterial growth, making it essential for industries with strict hygiene standards.

- Heat Resistance: Stainless steel maintains its integrity under high temperatures, suitable for applications involving heat exposure.

- Low Maintenance: Its resistance to stains and ease of cleaning reduce maintenance efforts and costs.

Applications in Material Handling Equipment

Stainless steel is utilized in various material handling equipment, including:

- Stainless Steel Pallet Trucks

- Stainless Steel Mobile Scissor Lift Tables

- Stainless Steel High Lift Pallet Trucks

Conclusion

Choosing stainless steel for material handling equipment offers numerous benefits, including durability, hygiene, and low maintenance. Its properties make it a valuable investment for industries aiming for efficiency and longevity in their operations.

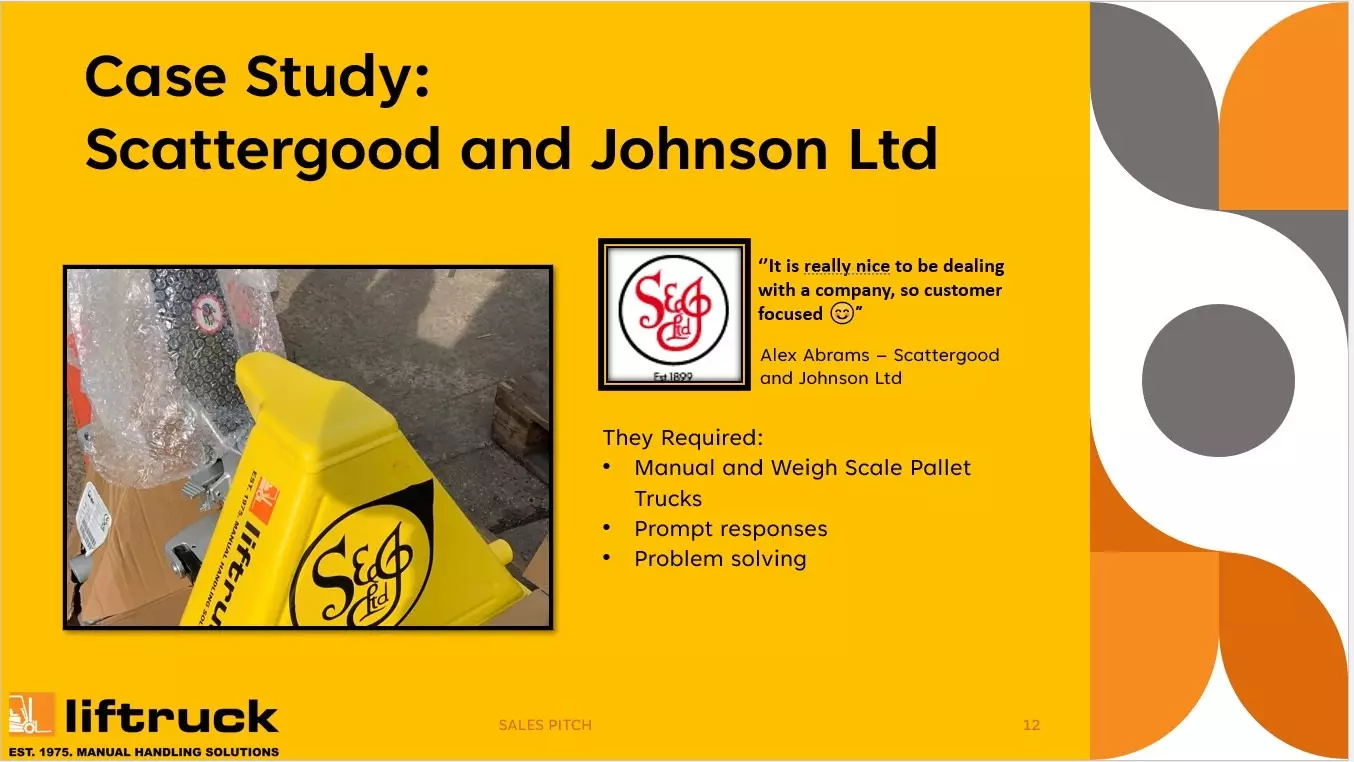

Contact Us

For more information on our range of stainless steel material handling equipment, please contact us at info@liftruck.co.uk or call 0800 458 8025.