Understanding Fork Extensions: Benefits, Legal Limits, and Best Practices

Fork Extensions are a crucial tool for material handling, enabling businesses to handle oversized or awkward loads more efficiently. While they offer many advantages, it’s important to understand their legal limitations and ensure safe use in compliance with industry standards.

In this blog, we’ll explore the benefits of using fork extensions, the legal restrictions — including length limits — and some best practices for safe operation.

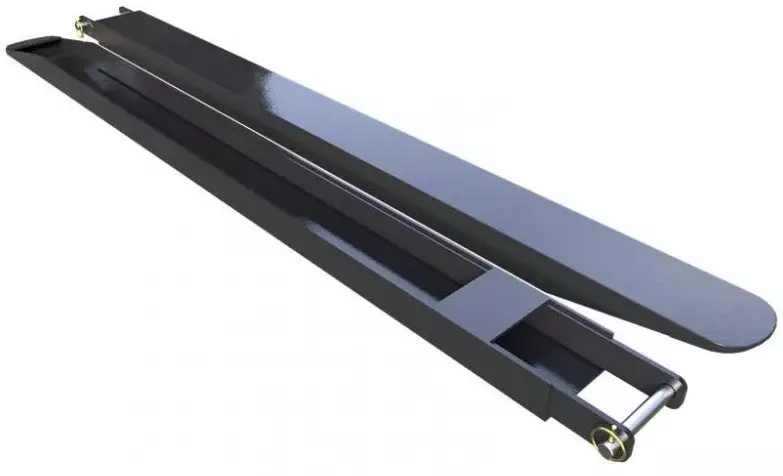

What Are Fork Extensions?

Fork extensions are attachments that slide over a forklift’s original forks to extend their length, allowing the operator to move longer or bulkier loads. These extensions are typically made from durable steel and are secured with locking mechanisms to prevent movement during lifting or transportation.

They are commonly used in industries such as warehousing, logistics, construction, and manufacturing, where standard forklift forks may not provide enough length to safely carry certain loads, such as long pallets or pipes.

Benefits of Fork Extensions

Fork extensions offer several operational advantages:

1. Increased Versatility

By extending the length of the forklift’s forks, operators can handle larger or longer loads that would otherwise be unmanageable. This added reach is particularly useful in industries dealing with oversized products or materials.

2. Improved Efficiency

Fork extensions enable fewer trips when moving large or long items, which can significantly improve operational efficiency. This allows workers to transport more items in less time, reducing downtime and labour costs.

3. Cost-Effective Solution

Rather than investing in larger or specialised forklifts, fork extensions provide a simple, cost-effective way to enhance the capabilities of existing equipment. This avoids the need for expensive upgrades or additional machinery.

4. Reduced Load Damage

Using fork extensions helps evenly distribute the weight of larger loads, reducing the likelihood of damage. This is especially important for fragile or high-value items that may be compromised if not properly supported.

Legal Limits for Fork Extensions

Despite the clear benefits, fork extensions must be used within specific legal parameters to ensure safety and compliance. These regulations are designed to prevent accidents, injuries, and equipment damage.

Length Restrictions

According to safety standards, including OSHA (Occupational Safety and Health Administration) guidelines, the length of the fork extensions should not exceed 166% (an additional 66%) of the original fork length.

For example, if the original forks are 48 inches long, the maximum allowable length of the fork extensions would be approximately 80 inches (48 + 66% = 80 inches). Exceeding this length can compromise the stability of the forklift, making it more prone to tipping or mishandling loads.

2. Load Capacity

While fork extensions allow for larger loads, they do not increase the forklift’s overall load capacity. In fact, the farther a load is placed from the forklift’s mast, the more it reduces the forklift’s lifting capacity due to the shift in the centre of gravity.

Forklift operators must always refer to the manufacturer’s load capacity charts to ensure they are within safe operating limits, especially when using fork extensions.

3. Securing Fork Extensions

Legal guidelines require that fork extensions be securely fastened to the original forks. Extensions typically come with locking mechanisms or pins that ensure they stay in place during lifting and transportation. Operators should always verify that these locks are properly engaged before use.

4. Operator Training

It is important that operators are trained to handle the forklift’s altered dynamics when using extensions. F orklift behaviour, such as steering and load handling, can change when the centre of gravity shifts due to longer forks. Proper training reduces the risk of accidents and ensures efficient operation.

Best Practices for Using Fork Extensions Safely

To maximise the benefits of fork extensions while ensuring safety, follow these best practices:

1. Choose the Right Extension Size

Always use fork extensions that are compatible with your forklift’s forks and comply with the **166% length rule**. Ensure they are appropriate for the load you intend to lift and are within legal length limits.

Some high-quality options include:

- Heavy Duty Extension Sleeves - https://www.liftruck.co.uk/forks-extensions/heavy-duty-extension-sleeves.html: These sleeves are designed for heavy-duty operations and can help you extend the capabilities of your forklift while handling bulkier loads.

- Heavy Duty Fork Extensions - https://www.liftruck.co.uk/forks-extensions/heavy-duty-fork-extensions.html: Ideal for heavier applications, these extensions are built to manage tough and oversized loads while maintaining safety.

- Triangular Fork Sleeves - https://www.liftruck.co.uk/forks-extensions/triangular-fork-sleeves.html: These uniquely shaped sleeves provide additional support for loads with specific shapes, helping improve load stability and transport efficiency.

- Radius Top Fork Sleeves - https://www.liftruck.co.uk/forks-extensions/radius-top-fork-sleeves.html: Perfect for handling delicate or rounded items, these sleeves are designed to reduce the risk of damaging sensitive loads.

2. Inspect Extensions Before Use

Before using fork extensions, inspect them for any signs of wear or damage. Ensure that the locking mechanisms are functional and that the extensions fit securely over the original forks. Damaged extensions can lead to safety hazards or equipment failure.

3. Understand Load Dynamics

When using fork extensions, it is critical to understand how the shift in the centre of gravity affects the forklift’s stability. Operators must ensure the load is evenly distributed and not exceed the forklift’s adjusted capacity. Always keep loads as close to the mast as possible for better balance.

4. Operate with Caution

Forklift handling can change with longer forks, so operators should adjust their driving behaviour. This includes taking wider turns, slowing down to account for the longer reach, and ensuring the load is stable before lifting or transporting it. Visibility may also be affected by the longer forks, so operators should communicate clearly with spotters or coworkers.

5. Adhere to Legal and Safety Guidelines

Ensure compliance with relevant safety standards, such as OSHA, when using fork extensions. Keep all equipment properly labelled and documented to ensure adherence to regulations and reduce the risk of penalties or accidents.

Conclusion

Fork extensions are an incredibly useful tool for extending the capabilities of standard forklifts, providing businesses with enhanced versatility, efficiency, and cost-effectiveness. However, to enjoy these benefits safely, it’s crucial to stay within legal limits, particularly regarding the 66% length increase rule, and to ensure proper training and safety measures.

By adhering to these guidelines and following best practices, you can use fork extensions to improve your material handling processes while maintaining a safe work environment. Remember, safety and compliance are key to avoiding accidents, legal consequences, and unnecessary downtime.