How to Measure Your Forklift Forks & Understanding Wear Limits

Ensuring your forklift forks are in optimal condition is critical for safety, efficiency, and legal compliance. Over time, forks wear down, reducing their lifting capacity and posing a risk to operations. In this guide, we’ll explore how to measure forklift forks, understand legal wear limits, and determine when replacement is necessary.

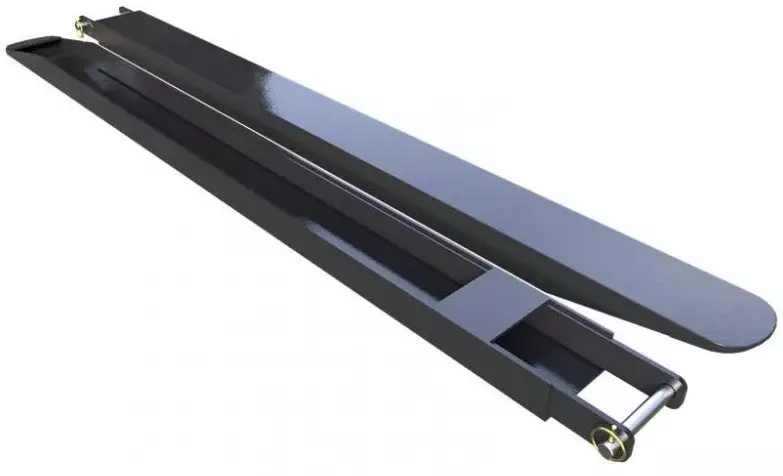

Understanding Forklift Fork Terminology

Before measuring your forklift forks, it's important to understand their key components:

- Blade: The horizontal part of the fork that inserts under the load.

- Shank: The vertical section of the fork that mounts onto the carriage.

- Heel: The point where the blade and shank meet.

- Tip: The front end of the blade.

- Hooks: The upper and lower fittings that attach the fork to the forklift carriage.

How to Measure Your Forklift Forks

Accurate measurement of forklift forks ensures compatibility and safety. Follow these steps:

- Fork Length (Blade Length - L): Measure from the front face of the shank to the tip of the blade.

- Fork Width (W): Measure the horizontal distance across the top of the blade.

- Fork Thickness (T): Measure the vertical thickness of the blade near the heel. This is critical for assessing wear.

- Back Height (BH): Measure from the bottom of the blade to the top of the shank.

- Mounting Class: Identify the ITA/FEM class of your forks for proper fitment.

To make this process easier, we recommend using a Forklift Fork Measuring Caliper to ensure precision.

Forklift Fork Mounting Classes

Forks are categorized based on carriage height and hook spacing, following ISO standards:

- Class II: 16 inches (407 mm) carriage height.

- Class III: 20 inches (508 mm) carriage height.

- Class IV: 25 inches (635 mm) carriage height.

Legal Wear Limits for Forklift Forks

According to safety regulations, forklift forks must be replaced when they wear down by 10% of their original thickness. A 10% reduction in thickness results in a 20% loss in load capacity, posing a safety risk.

Example: If your forklift fork was originally 50mm thick, once it wears down to 45mm, it must be replaced.

To ensure compliance, use our Forklift Fork Wear Caliper to measure wear accurately.

Key Inspection Criteria

Beyond measuring wear, consider these key inspection points:

- Cracks and Surface Damage: Check for cracks, particularly near the heel.

- Fork Alignment: Ensure that both forks have the same tip height.

- Fork Angle: The angle between the blade and shank should not deviate by more than 3 degrees.

Ordering Replacement Forklift Forks

When forks reach their wear limit, replacing them promptly is essential. At Liftruck UK, we source high-quality forklift forks from Cascade Corporation, a global leader in fork manufacturing.

To order replacement forks, follow these steps:

- Download and Complete the Quick Quote Form:

Download the Forklift Fork Quick Quote Form

- Submit Your Order: Email the completed form to info@liftruck.co.uk or call 0800 458 8025 for assistance.

Explore Our Range of Forklift Forks

We stock a wide range of replacement forklift forks suitable for all applications. Browse our product selection here:

Conclusion

Regularly inspecting and measuring forklift forks is crucial for maintaining workplace safety and efficiency. By following this guide, you can ensure compliance with legal wear limits and prevent equipment failures.

If you have any questions about fork compatibility or need assistance, contact our team today.

Contact Us

- Email: info@liftruck.co.uk

- Phone: 0800 458 8025

- Visit Our Forklift Fork Page